Energy Transfer Marcus Hook Industrial Complex

Dock 1A, 2A, and Fire Water Pump EPC Contracts

Project Overview

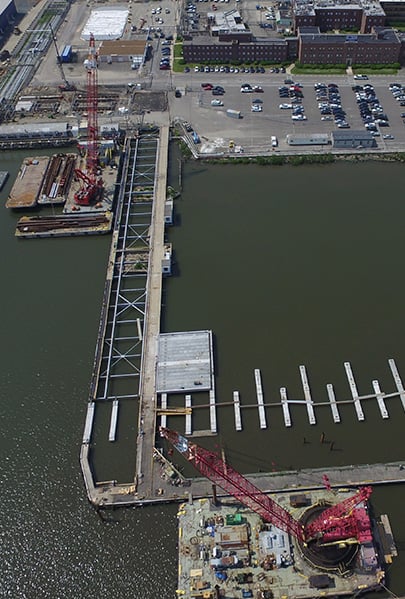

S. T. Hudson Engineers, Inc. was selected by Sunoco Logistics Partners, L.P. to design & construct a new dock for the loading of ethane, propane, and butane at the Marcus Hook Industrial Complex in Marcus Hook, PA.

Project Stats

Work for all three projects took place over the course of three years. Below you will find the improvements that S. T. Hudson made for each project.

Dock 2A Modifications (Sept 2013 – Dec 2016)

Total Project Budget = $21,000,000

New Structures:

- Breasting dolphins with rock anchor foundations

- Fender systems

- Mooring quick release hooks

- Gangway system

- Jib crane

- Dock house operations center

Dock 1A Rehabilitations (Jan 2016 – Dec 2016)

Total Project Budget = $75,000,000

New Structures:

- Dock platform, roadway, and pipeway

- Breasting dolphins

- Mooring dolphins

- Fender systems

- Mooring quick release hooks

- Fully automated gangway system

Firewater Intake System (Nov 2015 – Nov 2016)

Total Project Budget = $27,300,000

New Additions:

- Permanent cofferdam water intake bays

- Concrete intake structures

- Automated firefighting pumping system

- Underground water piping system

- Electrical, mechanical, and instrumentation integration and commissioning

Project Data Points

950

Linear ft of

Pipe Rack Modules

Most of the models were more than 80ft in length and over 15ft tall.

6

New Mooring

Dolphins Added

as well as 2 new breasting dolphins and 2 new breasting coffercells.

8

New Walkways

Constructed & Installed

Connecting all 10 new dolphins to incorporate the complete dock upgrade.

1

New Gangway

And Crane Tower

Estimating, purchasing, and construction services.

Project Results

The project involved three separate projects: the rehabilitation of Dock 1A, a rehabilitation and upgrade of Dock 2A, and the retrofit installation of a fire water intake system on Dock 1A.

Due to the extensive work to be completed as well as the complexity of the project, S. T. Hudson was able to provide a range of services. Hudson’s scope of engineering services included a detailed OPTIMOOR analysis, conceptual design, cost estimates, engineering calculations, construction documents and federal and state permits and construction management services. This project demonstrated Hudson’s capacity to carry a project through every phase of the project cycle.

In all three projects, the major challenge was to take an aging existing infrastructure and retrofit it to accommodate the newest class of LPG tanker vessels. This required major modifications to the existing structures, which had to be achieved without damaging their structural integrity. We also overcame logistical challenges in transporting and installing the large prefabricated pipe modules that are necessary to safely transfer the product from refinery to the vessels.

Project Goals

Before S. T. Hudson completed this work, this facility was a dormant refinery. The upgrades that we recommended, designed, and helped to construct turned this facility into a major export terminal that takes petroleum products, piped in from western PA, and sends it to markets in Europe, while creating thousands of new jobs for the local community.