Your Mechanical Engineering Consultants

To build sound marine and terminal structures, you need the expertise of a professional mechanical design engineer. S. T. Hudson is your solution.

Mechanical Design Engineers & Consultants

S. T. Hudson provides mechanical design services that are necessary for marine and in-shore design projects. We design mechanical systems for a wide range of commercial enterprises, including cargo and vessel transfer, heavy piping, pollution control, chemical and petroleum terminals, refineries, and industrial and manufacturing facilities.

Our knowledgeable group of engineers have decades of experience in operations, maintenance, capital improvements, turnarounds, and other construction planning issues. We pull from this extensive knowledge base and work on behalf of our clients to ensure that our planning, design, and construction efforts will result in successful projects.

Our Process

To stay on track and ensure we deliver consistent results, we utilize a step-by-step process for mechanical engineering projects.

- Due Diligence

Whether we’re evaluating the restarting of old plants and facilities, investing in new or existing plants, upgrading and modernizing old processes, increasing the capacity of existing facilities, or extending a facility’s lifespan, we offer innovative and practical solutions to any problems encountered.

- Conceptual Design

As the first step in a project, the purpose of the conceptual design phase is to determine high level parameters such as purpose, production, place, and price—accounting for around 50% of the total cost.

- FEED Studies

A complete FEED (Front End Engineering and Design) package will prove the feasibility and the cost estimate from the concept design. With this, we address all of the client’s project requirements, which will ideally minimize the need for changes in subsequent stages of the design.

- Detailed Design

During this phase, the budget, design details, and all project plans and specifications will be completed to be approved for construction. This is the last chance to make any significant changes to the design.

- Project Management

Project management involves planning, implementing, monitoring, controlling, and closing out a project to meet measurable criteria detailed by the scope, schedule, budget, and plans for the project. We utilize tools such as cost tracking and cost control, scheduling, estimating, and risk analysis to steer the project to success.

- Cost Tracking / Control

We keep the project budget under control by adhering to and monitoring the project plan, project scope, estimate, and schedule. To avoid surpassing the project budget, we adopt a strict change management process when we identify and track variances.

- Scheduling

Scheduling transforms the project plan into a manageable set of steps. We set deadlines and allocate resources, regularly reviewing and revising the plan as needed while it is in execution. The schedule continues to evolve as the project progresses, as variations develop, and risks are identified, handled, or eliminated.

- Estimating

From the conceptual to final phase, our estimating follows the American Association of Cost Engineers (AACE) recommended practices. We utilize advanced estimating systems such as Aspen Capital Cost Estimator (aka Icarus Kbase). We also validate and independently evaluate estimates, re-casting for project ranking criteria, as well as conduct a project risk analysis and contingency review.

- Hydraulic Analysis

Utilizing a complete piping design and analysis software package, we can provide a conceptual understanding of the entire piping and component system. This will enable the calculation of how the system operates, including pressures, flow rates, and net positive suction head available.

- Stress Analysis

Stress analysis is performed to verify that a piping system is routed and supported properly. The analysis determines movements and loads throughout the system from which the stresses in the piping material are calculated and checked for compliance to applicable codes.

- Marine Vapor Recovery Design and Certification

We design marine vapor control systems to safely and efficiently destroy explosive vapors from marine cargo vessels during hydrocarbon loading activities. We can also certify that new or existing systems meet all state and federal regulatory requirements for the control of VOC emissions.

- Laser Scanning

We document existing conditions to propose a change and create the initial design with laser scanning. This allows all the designers to see the actual conditions of the selected site and design within the scan instead of having to make repeated trips to the field.

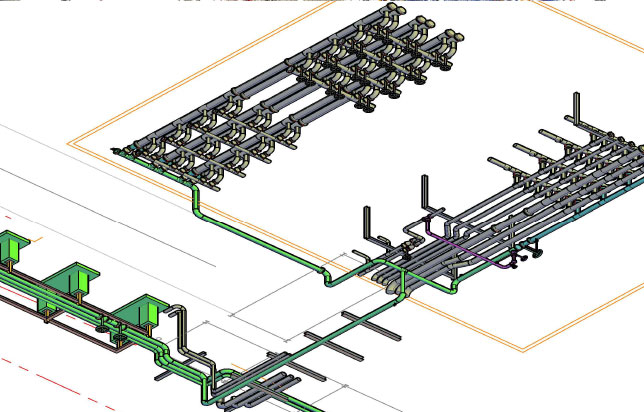

Obtain accurate and reliable information on piping systems, tanks, and other industrial systems with Laser Scanning and 3D Modeling.

Laser Scanning and 3D Modeling

With S. T. Hudson’s advanced Laser Scanning and 3D Modeling services, you can quickly capture precise 3D documentation of the existing facility with accurate measurements to assist in the planning phases for alterations and expansions of your equipment and structures, helping to reduce time in the field. Laser Scanning technology makes as built data collection simple, precise, accurate, and cost-effective.

Our data collaboration process gives you clear, detailed insights into the information we collect, with a user-friendly online system that makes it easy for you to access data. By having a more complete picture of your project, you’ll be able to make more accurate decisions.

We take care of data collection and processing in-house, which means we won’t have to bring in additional contractors—ensuring a quality process from start to finish.

Our Laser Scanning and 3D Modeling can advance your engineering projects in various ways. With Laser Scanning and 3D Modeling, you will get:

- Field Survey – Decrease field survey times with fewer personnel and lower risk due to less exposure to operating facility.

- Data-Driven Designs – Create modifications, using the 3D Modeled data gathered, that can be interlaced into existing structures, eliminating interference. Modifications can be shared real time for review and approval.

- Insight Into Issues - Identify potential spacing, access, and maintainability issues .

- Accurate Data - Accurately quantify pipe sizes and tank volumes.

- Component Models - Generate accurately-sized models of existing components.

- Dimension Verification - Verify dimensions of equipment such as heat exchangers, pumps, and other equipment.

- Planning Data – Identify equipment maintenance access, laydown, crane positioning, and other Operability and Maintainability functions.

ST Hudson was there when it counted and you should be applauded.

South Jersey Port Corporation -

See Our Experience

Energy Transfer Marcus Hook Industrial Complex

Addition of a New Fire Water Intake System

Learn more +

Pro Tips

Marine Vapor Recovery systems are required to undergo an Operational Review every five years by a Coast Guard Approved Certifying Entity.

Storage tanks changing from heated service to ambient temperature service in colder climates need to be assessed for brittle fracture failure.

It is good practice to install a check valve at the discharge of every pump.

Initial design or design modifications to Marine Vapor Recovery (MVR) Systems need to be certified by a Coast Guard Approved Certifying Entity not affiliated with the design engineer.

Eccentric reducers are installed in pump suction piping to minimize accumulation of any air or gas bubbles in the suction.