An Opportunity for Growth

Buckeye’s Gulf Coast regional hub in Corpus Christi is a world-class operation offering marine terminalling, storage, and processing for liquid petroleum products. When another company added new neighboring pipelines, Buckeye saw an opportunity to expand their capacity. Buckeye enlisted S. T. Hudson to help them connect their oil terminal to these adjacent pipelines—increasing the potential for throughput and profits.

Project Goals

Buckeye’s success relies on their ability to transport as much product as possible. Therefore, any opportunity to expand operations offers an advantageous edge. The goals for this project were focused on improving Buckeye’s capacity to move products through their terminal and into the pipelines.

Gain Precise Measurements

Buckeye needed to understand the sizes required for the addition. Laser scanning would provide accurate measurements.

Move More Product

Connecting to adjacent pipelines would allow Buckeye to transport product from their terminal and out into the new pipeline network.

New Way to Get More Throughput

By utilizing piping tie-ins, Buckeye could pursue an additional avenue to increase profits.

Key Data Points

3

Separate

Tank Fields

10,000

Feet of

Piping Tie-Ins

10

Months

Start to Finish

Project Details

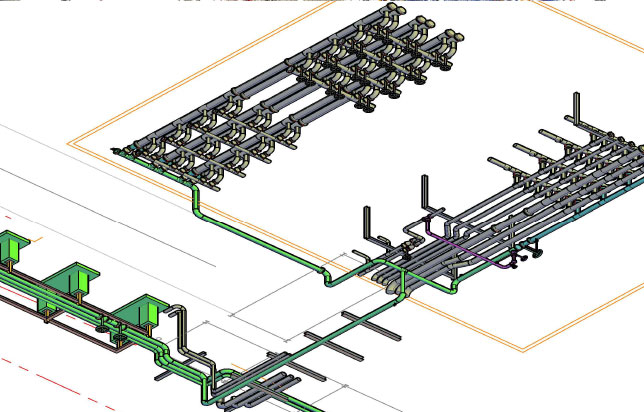

Using state-of-the-art 3D laser scanning equipment to model existing conditions, S. T. Hudson created accurate 3D models to design the connection of the Buckeye Texas Processing tank fields to third-party exporting pipelines. The 3D models enabled S. T. Hudson to remotely design the manifold connections, rack piping, and piping tie-ins, eliminating the need for multiple trips to the site.

Buckeye Partners transports oil products, including crude, gasoline, and diesel, from their terminal and into pipelines for various types of customers. Located in Corpus Christi, their Gulf Coast hub provides world-class terminalling, storage, and processing. When another pipeline company was installing new oil pipelines that ran adjacent to the Buckeye Corpus Christi terminal, Buckeye wanted to be able to connect three separate tanks to these new pipelines—which would greatly expand their capacity to move oil products.

The project began with an assessment of the current facility. Using the already-existing pipes, S. T. Hudson was tasked with figuring out what size new piping had to be to accommodate the new specifications and needs, as well as where piping needed to be connected. Additionally, Buckeye knew that they wanted to move a certain amount of product per hour, requiring S. T. Hudson to do hydraulic modeling and calculations to determine the appropriate sizing to accommodate this. Using the information gathered from 3D laser scanning, the S. T. Hudson team was able to create precise 3D models to build the necessary additions.

Project Highlights

- Robust assessment to create full project scope

- Hydraulic modeling to determine proper sizing

- 3D laser scanning of existing manifold areas and pipe racks

- 3D modeling of existing manifold areas and pipe racks

- Manifold design of piping tie-ins to export pipeline

- Piping and pipe support design